RecommendProduct

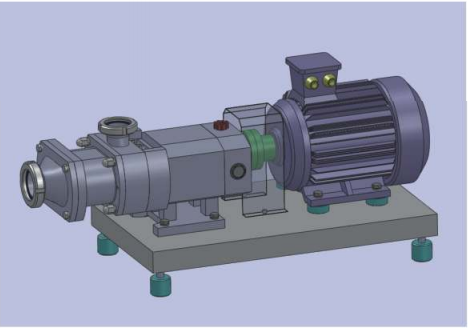

twin screw pump

In the pharmaceutical,food,beverages,cosmetics,fine chemical industry and so on many areas of industrial production and processing,often ishighly sensitive to the shear stress of the product transportation problem,these products also tend to have higher viscosity.Such as biological products,blood products,enzyme preparation,yogurt,chocolate,all kinds of pulp,pulp,yeast solution,cosmetics and so on.Different products for a long time,for this kind of conveyor designed a variety of solutions,such as all kinds of rotor pump,screw pump,bias peristaltic pump,gearpump,diaphragm pump,sine pump,plunger pump and so on.These according to different process and product design solutions,exist widely in the industrial production practice versatility and compatibility is poor,equipment use and maintenance cost is high,large energy consumption,high investment cost and so on equipment system as a whole defects and other problems.According to the production problem,Jonhen company research and development team,after years of unremitting efforts,toexplore,experiment,trial and error in production factory,has finallysuccessfully developed with international advanced technology level,canbe widely suitable for various

kinds of viscosity materials,various processconditions and production conditions.

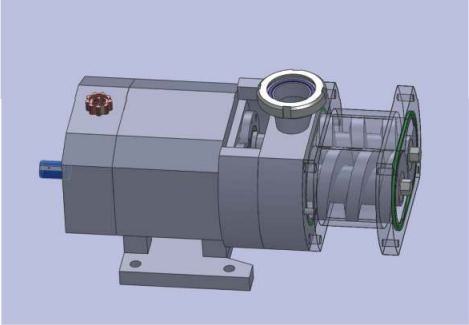

Unique working principle

Is an expert in production technology and equipment of the new manufacturing fusion result.A pair of special designed screw system,meshing,using modern processing technology and means (such as edmtechnology,laser cutting,multiaxis linkage CNC programming processing center,etc.),to ensure that the relative motion in the pumpbody double rotor does not exist any direct contact between the metal.From the design and structure on the guarantee system work togetherwithout contact,no wear and tear,so as to ensure the trouble-free of equipment system,long life.wall,between the inlet and outlet of the pump,can be divided into a seriesof multiple sealed space.With the rotation of the screw and the meshing,the sealed space in pump suction side continuous formation,the liquidfrom the suction chamber seal in among them,and since the suctionchamber along the screw axial continuously goes on to the discharge end,will be closed in each independent space of liquid continuous,smoothdischarge,like a nut in screw rotation being constantly move forward,thisis Twinsman,parallel displacement pump,the basic working principle.

|  |

Double screw pump

UseaTwinsman can replace the four difrent pump at the same time(santary rotor pump,screw pump,self-priming pump,sanitary centriugalpump) use Twinsman has more powerful function,higher productionefficiency,lower energy consumption,longer service life,lower operationand maintenance costs.

■winsman not rotor pump,but better than that of the rotorpump,can replace rotor pump:

■Twinsman direction the same as the direction of material flow,so to materialdestruction and stirring;

■Twinsman for material without any extrusion,shear,damage;Can finish delivery the wholeof the granular material

■Twinsman can at high speed,maximum speed is 4000 RPM,itis available rather than theordinary motor gear motor;

■Twinsman not screw pump,but better than the screw pump,screw pump can replace:

■Twinsman only move rotor synchronous,no contact with richgrand or rubber stator structure,

■Twinsman no contact between the metal,so that the work of nogrinding damage,do not need tochange the rotor spindle on aregular basis.

■Twinsman unique dynamic rotation surface sealing structure,guarantee in the pump cavity formation higher and more stablevacuum environment,

■Twinsman can not only replace self-priming pump: CIPcleaning and CIP back to liquid delivery,and even if there is agas,also do not produce water hammer effect,equipmentsystemalso can work normally.

■Twinsman not ordinary centrifugal pump,but better than the centrifugal pump,can replacethe centrifugal Pump,especially high pressure centrifugal pump:

■Twi nsman can not only stable high voltage output,can achieve16 normal bar,and evenin the particles,gas flow rate

Extraordinary characteristics and functional features

Parallel to the working principle and structure characteristics of displacement conveying system,determines the Twinsman has thfollowing advantages:

■Wide range of pressure and flow.Pressure around 6-25 bars,flow rateof 235 m3 /h;

■Delivery and type of liquid viscosity range: all kinds of viscosity of the fluid can bedelivery;IBecause the rotary inertia force component inside the pump is low,socan use very high speed,maximum speed of up to 3900 revolutions perminute;

■Aspiration can be good,has the special outstanding self-primingcapacity;

■Flow uniformly continuous,small ripple,small vibration,low noise;

■Compared with other rotary pump,the gas and particles is not sensitive to enter,can undertake gas liquid,solid liquid mixed transportation;Solid structure,modular structure,installation and maintenance easy.

The structure of double of double screw pump,structure、materials

Double screw pump with open,health structure design,the entiredevice composed of pump body,gear box,motor of the three mainparts.Double screw pump adopts full stainless steel,all and material contact part is made of high quality 316 stainless steel,transmissionpartadopts 304 stainless steel ;Pump body is the core component,by the former cavity cover andcavity,the screw rotor,shaft,machine seal cavity,such as mechanicalseal parts;Drive system is composed of a drive shaft and a driven shaft,each matching mounted on the shaft screw sets.Delivery process is through hand a reverse of the synchronous gear drive shaft installed in thecompleted.Synchronous gear with high precision simultaneous helicalgear.ensure smooth operation.Gear box adopts 304 stainless steel,andimprove the healh level of the equipment.

Application field

■Pharmaceutical industry: all kinds of liquid medicine, blood products, biological products, sugar, all kinds of ointment, glucose, oral liquid, etc.;

■Dairy industry: milk, cheese and curd, butter, fruit yoghurt, icecream, all kinds of oil,all kinds of stabilizer, etc

■Foodi ndustry :yeast, pasta, fruit fllings, sugar, fat and oil,all kinds of jam,mayonnaise,mashed potatoes,starch,vegetablesoup,soy sauce and other spices,chocolate,cream,spongecake,filling and fat,margarine,etc.;

■Meat product industry :sausage stuffing, fat, broth, gel, all kinds of meat, pet food, etc

■Canned food industry: potato salad, soup, stew, tomato, appetizers, pudding, spice,jams and jellies

■Beverageindustry: beer,malt juice,fruit juice,concentrationfruit juice,syrup,chocolate,cocoa butter,corn syrup,gel type,etc

■Cosmetics industry: all kinds of perfume, skin cream ,showergel, gels, shampoos, lotions,toothpaste,etc

■Chemical industry :automotive paint, printing ink, rubber, paint, enamel, detergents,Polymers ,resins, etc.;

|  |

Double screw pump technology parameters

型号规格 | 流量 | 进出口 | 调节范围 | 压力 | 电机功率 | |

JLS-90 | 3000 | DN50 | DN50 | 200~2900 | 6~20 | 2.2~4.0 |

JLS-110 | 6000 | DN65 | DN65 | 200~2900 | 6~20 | 5.5~7.5 |

JLS-140 | 15000 | DN80 | DN80 | 200~2900 | 6~20 | 11~18.5 |

JLS-160 | 30000 | DN80 | DN80 | 200~2900 | 6~20 | 22~30 |

JLS-200 | 50000 | DN100 | DN100 | 200~2900 | 6~20 | 37~55 |

返回列表

返回列表